To make a container for the silicone, use a plastic container that is just a little bit bigger than the object you want to copy. Mold Star® silicones cure to soft, strong rubbers which are tear resistant and exhibit very low long-term shrinkage. Molds made with Mold Star® will last a long time in

Find All Your Needs in Thermosetting Polyurethane, Epoxy, & Silicone Systems Worldwide. Customizable Solutions for Rotational Moulding & Silicone Molds.

![]()

![]()

High Performance Silicone Mold Release is Formulated for use as a Release Agent for Injection Molders.

Tin-based silicone, also called condensation-cure silicone, are two-component materials which cure at room temperature (RTV) to flexible, high tear-strength rubbers.

We specialize in helping you turn ideas into physical reality by showing you mold making and casting materials that do things you never thought possible.

MakeYourOwnMolds.com specializes in food grade silicone mold rubber, free tutorials & mold making videos that teach you how to make your own silicone molds

I chose a figurine from a comic shop as my demo to mold. This will be what is called the master. It has a fair amount of surface detail, and some small parts that, although tricky, are faithfully reproduced in the final casting. Begin by inspecting, cleaning, and securing your model. I glued down

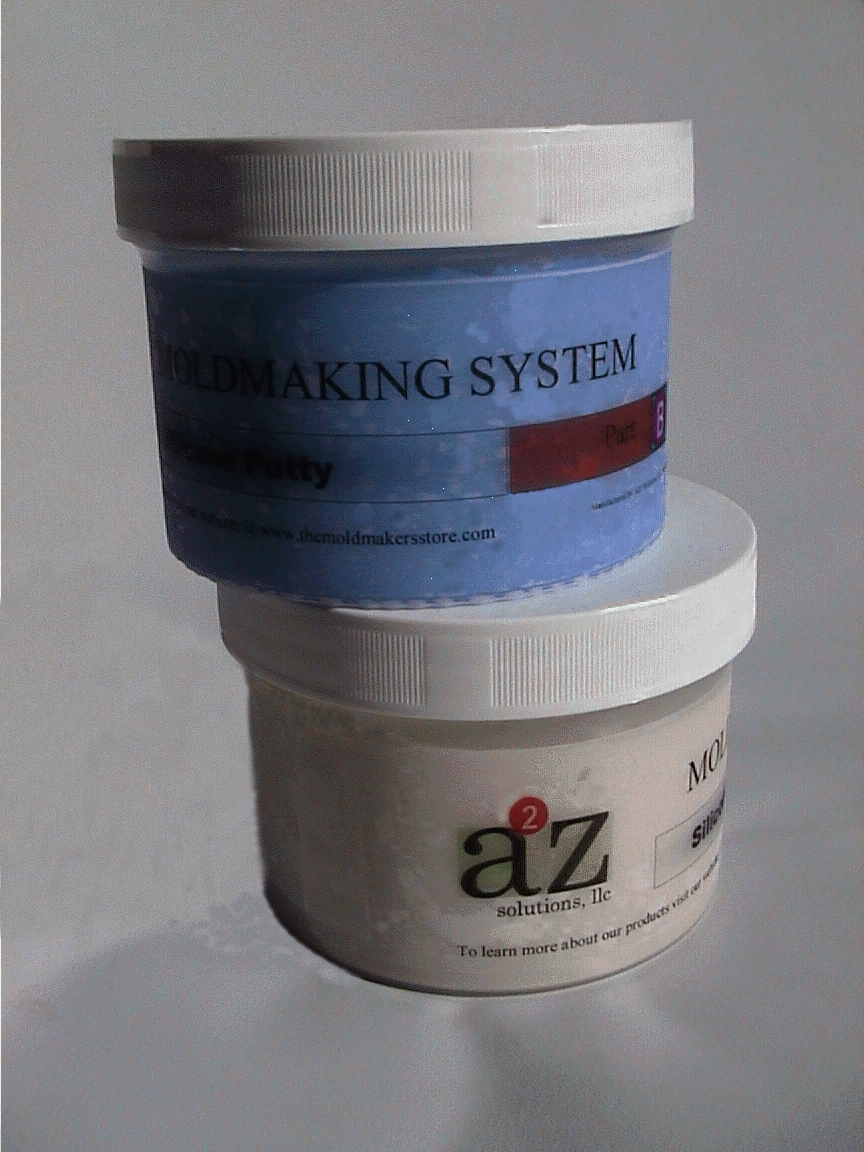

Once mixed, Silicone Plastique® will stay workable for about 15 minutes giving ample time to make an accurate and well made mold of almost any object.

![]()

As a low-taint, non-toxic material, silicone can be used where contact with food is required. Silicone is becoming an important product in the cookware industry, particularly bakeware and kitchen utensils.

![]()

![]()

![]()

Taking off from this BRILLIANT ‘ible https://www.instructables.com/id/How-To-Make-Your-Own-Sugru-Substitute/ I have started making silicone molds on the cheap

![]()